How Wool is Made

Quick Links

- Archived - Ask a Knitting Question

- Basic Knitting Stitches

- Beginner Knitting Patterns

- Knitting Abbreviations

- Needle Sizes Chart

- Tension Squares

- Yarn Comparison Chart

FYI: This site receives a small amount in commissions from affiliate links and third-party advertising.

Ever wondered how wool is made? Although the phrase wool is used these days to describe a wide variety of yarns including man-made fibres, the term wool originally referred to the fibre grown by sheep.

The basic process of making wool is the same whether you are talking about a crafts-person hand spinning their wool or a commercial manufacturer. All that changes is the scale, the kind of tools or machine that are used and sometimes the fibres that are spun into yarn..

As most hand-spinners are aware, fleece wool is ideal for spinning for two reasons.

First, the wool has a natural coating of grease or lanolin which protects the sheep from the elements and provides insulation, and second, because the fibres cling to each other.

© Jim, the Photographer | Flickr Old Spinning Wheel

Hand Spinning - How Wool Is Made

First the fleece is cleaned, either by washing or by carding, to remove any debris from the fleece and to prepare the fibres for spinning. Once you have a clean fleece wool, it is a relatively simple process to make wool.

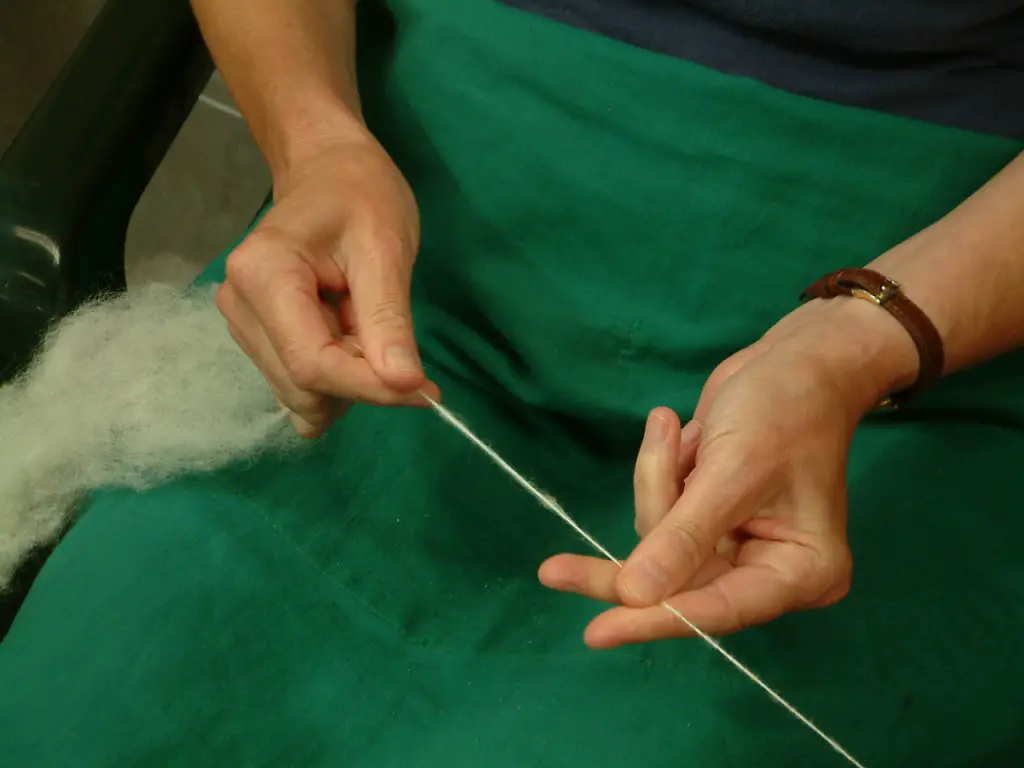

A small number of fibres are gently draw out of a lock of wool to the required thickness and then spun or twisted so that the fibres cling together into a single ply thread.

If you could look at the individual fibres under a microscope you would see that the fibres have an outer layer of overlapping scales. These scales act a little like tiny barbs which cling together as allowing the fibres to lock together during the spinning process.

© National Rural Knowledge Exchange | Flickr Hand Spinning

Once the drawn out thread is twisted, it is usually wound onto a holder of some kind (either a drop spindle or a bobbin). This maintains the tension of the thread and prevents the wool fibres from unravelling.

Once wound, more fibres are drawn out of the lock of wool and the process is repeated to form a continuous thread. If you wish to use your thread for weaving a single ply thread is sufficient, but if you want to knit the wool into a garment, you generally need a two ply thread.

To do this you twist two single ply threads together in the opposite direction.

Clear as mud? Let me explain it another way.

If your single ply was twisting in a clockwise direction, you ply your wool by twisting in an anti-clockwise direction. The plying action reduces the amount of twist in each of the single ply threads and binds the thread together.

Couldn't Find What You Were Looking for?

Try searching the site using the search box below:

Recent Articles

-

Shetland Knitting and Shetland Knitters

Feb 07, 21 07:44 AM

Shetland knitting and the women in the Shetland Isle who create Shetland lace are among the best knitters in the world. -

Fixing Knitting Mistakes

Jan 28, 21 02:35 AM

When you are learning how to knit, you are going to make a few mistakes. It might not make you happy but fixing knitting mistakes is par for the course. -

Shetland Lace Knitting

Dec 11, 19 07:03 PM

Shetland Lace Knitting is a particular style of knitting that developed in the Shetland Islands and was one of the main exports of the Island early in the last century.

>

>